Fire Clay

Fire clay is generally of sedimentary origin. Strictly speaking, fireclay is of sedimentary origin and mainly found in the coal measures, as bedded deposits.

A group of refractory clays which can stand temperatures above Pyrometric Cone Equivalent (PCE) 19 are called fireclay. The clay which fuses below PCE 19 is not included under refractory. Fireclay is essentially of kaolinite group and has a composition similar to that of china-clay. In nature it is usually found to contain 24-32 per cent Al2O3, 50-60% SiO2 and LOI between 9 to 12%. Impurities like oxides of calcium, iron, titanium and magnesium and alkalies are invariably present, making it white, grey and black in colour.

Like other clays, this clay is highly malleable in raw form. It can be molded, extruded, shaped by hand, and stamped. Various additives can be mixed in to make it more coarse, and it can be ground to be smoother. Slip and scraps for fire clay manufacturing can also be recycled, as long as they are not fired, and worked into new batches of clay for use. Fire clay also shrinks after it has been molded .

Refractoriness and plasticity are the two main properties in fireclay for its suitability in the manufacture of refractory bricks.

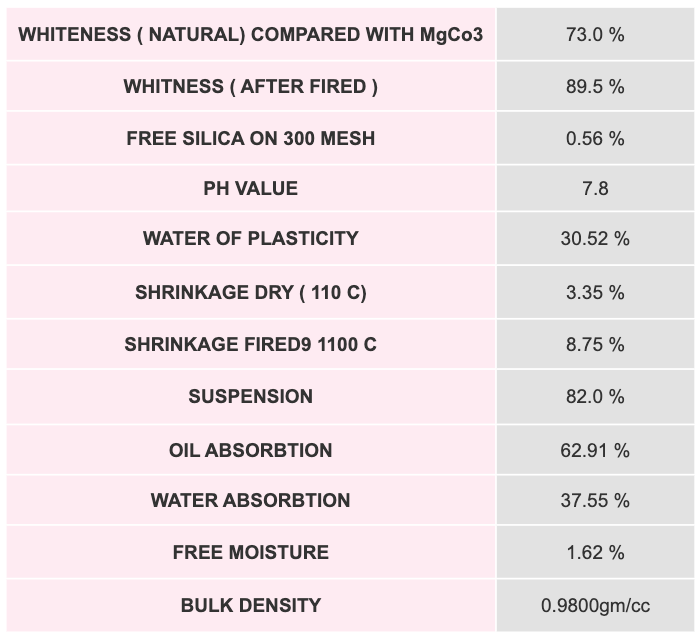

We can also supply the below mentioned minerals with the following specification:

USAGES

- Raw Material for Refractory Bricks

- In boiler furnaces

- Glass melting furnaces

- Chimney linings

- Pottery kilnsblast furnaces

- Reheating furnaces